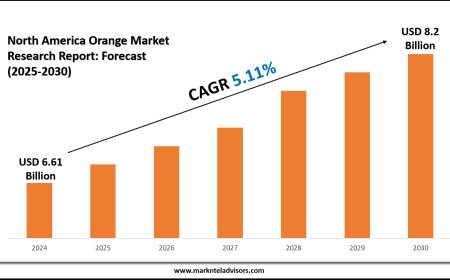

Silicone Elastomers Market Trends, Growth, and Demand Forecast 2025-2033

The global silicone elastomers market size reached USD 9.4 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 14.8 Billion by 2033, exhibiting a growth rate (CAGR) of 4.89% during 2025-2033.

Market Overview:

Thesilicone elastomers marketis experiencing rapid growth, driven by increasing demand in automotive applications, expanding use in medical and healthcare, and growth in construction and infrastructure. According to IMARC Group's latest research publication, "Silicone Elastomers Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The globalsilicone elastomers market sizereachedUSD 9.4 Billionin 2024. Looking forward, IMARC Group expects the market to reachUSD 14.8 Billionby 2033, exhibiting a growth rate(CAGR) of 4.89%during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Download a sample PDF of this report:https://www.imarcgroup.com/silicone-elastomers-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the Silicone Elastomers Market

- Increasing Demand in Automotive Applications:

Silicone elastomers are on the rise in the field of motorcar production, where they can be utilized effectively, because of their extraordinary, durability, flexibility, and tolerance of extreme temperatures. They are applied in gaskets, seals and hoses since they become dependable in engines and other key parts. As an example, the manufacturers of the electric vehicle (EV) product such as Tesla have used silicone elastomers as seal materials of the battery to prolong thermal stability as well as assure safety. The automotives industry is moving towards lightweight materials with the aim of making vehicles fuel efficient and emission friendly, silicone elastomers offer a sound solution. The hardiness to move in tough environmental conditions makes them unique and cannot be ignored hence a steady demand in any market around the world.

- Expanding Use in Medical and Healthcare:

Silicone elastomers are used in the medical industry, which is an important growth factor in the field promising flexibility and biocompatibility. They are common in the medical devices that include catheters, tubing and implants because they are non-reactive, and elicit highly charged regulatory assessments. An example is the Medtronic Company that makes use of silicone elastomers to manufacture pacemakers and insulin pumps; its processes have guaranteed the safety of patient usage and the reliability of the devices. Expanding demand and growing popularity of wearable medical devices and an increase in the number of minimally invasive surgeries add to the level of growth. With an increasing pace of healthcare innovation, especially in ageing demographics, demand on high quality and durable material such as silicone elastomers increases evermore.

- Growth in Construction and Infrastructure:

The use of silicone elastomers in construction increases with their use as sealants, adhesive, and coating because of their durability and resistance to weather conditions. They are well suited in such applications as windows knows as sealing, as well as structural glazing in high rise buildings. This is eminently observed in the use of silicone sealants in Burj Khalifa which were durable due to harsh weather conditions. With urbanization and infrastructure growth, especially in developing nations, there is increased demand of good longstanding material. Due to the practicality of them performing in various hot-weather conditions, the market growth of silicone elastomers is on a continuous increasing scale.

Key Trends in the Silicone Elastomers Market

- Rise of Eco-Friendly Silicone Solutions:

Sustainability is shaping the silicone elastomers market, with manufacturers developing eco-friendly formulations to meet environmental regulations. Companies like Dow are investing in low-volatile organic compound (VOC) silicones, reducing environmental impact while maintaining performance. These sustainable elastomers are used in green building projects and energy-efficient appliances, aligning with global sustainability goals. For instance, silicone-based sealants with reduced emissions are gaining popularity in LEED-certified construction projects. As consumers and industries prioritize eco-conscious materials, the shift toward greener silicone elastomers is becoming a defining trend, encouraging innovation and broader adoption.

- Advancements in High-Performance Formulations:

Technological advancements are driving the development of high-performance silicone elastomers tailored for specialized applications. These formulations offer enhanced properties like greater thermal stability and chemical resistance, catering to industries such as aerospace and electronics. For example, Momentive Performance Materials has developed self-lubricating silicone elastomers for automotive components, reducing friction and wear. The trend toward customization allows manufacturers to address specific industry needs, such as high-dielectric silicones for 5G infrastructure. As industries demand materials that perform under extreme conditions, ongoing research and development are pushing the boundaries of silicone elastomer capabilities.

- Growing Adoption in Consumer Electronics:

Silicone elastomers are increasingly integral to consumer electronics, driven by the demand for durable, flexible, and thermally stable materials. They are used in wearable devices, smartphone gaskets, and flexible displays, offering protection against moisture and heat. A case study is Apples use of silicone elastomers in Apple Watch bands, combining comfort with durability. As consumer electronics evolve toward smaller, more complex designs, silicone elastomers provide critical solutions for sealing and insulation. The rapid growth of the Internet of Things (IoT) and smart devices further accelerates this trend, positioning silicone elastomers as a cornerstone of modern electronics manufacturing.

We explore the factors propelling the silicone elastomers market growth, including technological advancements, consumer behaviors, and regulatory changes.

Leading Companies Operating in the Global Silicone Elastomers Industry:

- Bentec Medical

- China National Bluestar (Group) Co. Ltd.

- Dow Inc.

- KCC Corporation

- MESGO SpA (Hexpol AB)

- Momentive Performance Materials Inc.

- Reiss Manufacturing Inc.

- Shin-Etsu Chemical Co. Ltd.

- Specialty Silicone Products Inc. (Heico Corporation)

- Stockwell Elastomerics Inc.

- Wacker Chemie AG

Silicone Elastomers Market Report Segmentation:

Breakup By Product:

- High Temperature Vulcanize (HTV)

- Room Temperature Vulcanize (RTV)

- Liquid Silicone Rubber (LSR)

High temperature vulcanize (HTV) exhibits a clear dominance in the market due to its superior thermal stability and mechanical strength, making it ideal for high-performance applications in demanding environments.

Breakup By Application:

- Electrical and Electronics

- Automotive and Transportation

- Industrial Machinery

- Consumer Goods

- Construction

- Others

Automotive and transportation hold the biggest market share, as silicone elastomers are widely used in seals, gaskets, and hoses that require high durability, flexibility, and heat resistance in vehicles.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific dominates the market owing to its strong automotive industry, extensive industrial base, and stringent regulations promoting the use of high-performance materials in various sectors.

Research Methodology:

The report employs acomprehensive research methodology, combiningprimary and secondary data sourcesto validate findings. It includesmarket assessments, surveys, expert opinions, and data triangulation techniquesto ensureaccuracy and reliability.

Note:If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the worlds most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145